Nov 16th 2024

KYMCO UXV700i Service Manual

General Information

Make sure to install new gaskets, O-rings, circlips, cotter pins, etc. when reassembling.

When tightening bolts or nuts, begin with larger-diameter and move to smaller ones. Tighten bolts evenly and tighten to the specified torque diagonally.

Use genuine parts and lubricants.

When servicing the motorcycle, be sure to use the indicated special tools for removal and installation.

After disassembly, clean and inspect the removed parts. Lubricate sliding surfaces with engine oil before reassembly.

Apply or add designated greases and lubricants to the specified lubrication points.

After reassembly, check all parts for proper tightening and operation.

When two persons work together, pay attention to the mutual working safety.

Disconnect the battery negative (-) terminal before working on the vehicle. When using a spanner or other tools, make sure not to damage the motorcycle surface.

After working on the vehicle, check all connecting points, fasteners, and lines for proper connection and installation. When connecting the battery, the positive (+) terminal must be connected first. After connection, apply grease to the battery terminals. Terminal caps must be installed securely.

If the fuse is burned out find the cause and repair it. Replace the fuse with a new one according to the specified capacity.

After working on the vehicle make sure terminal caps shall have been installed securely.

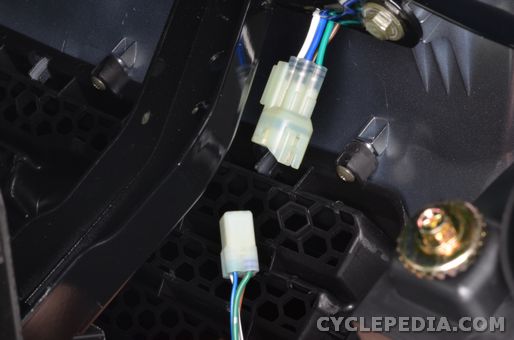

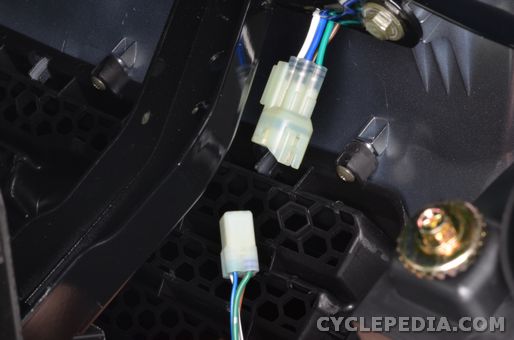

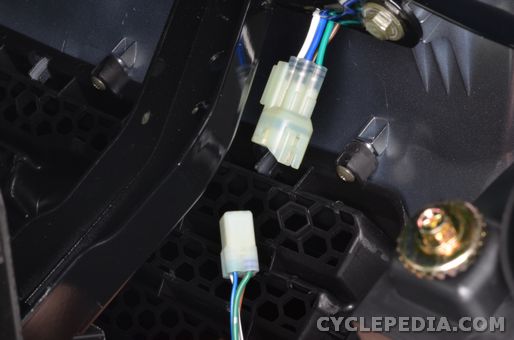

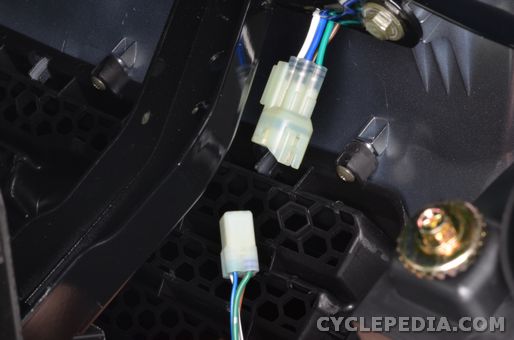

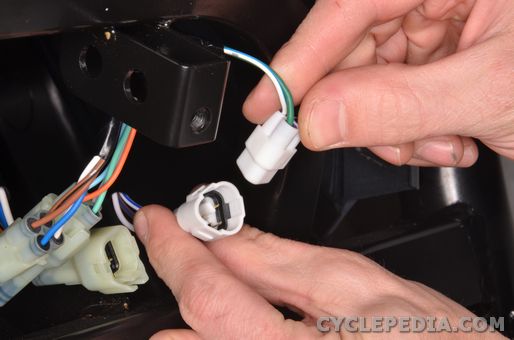

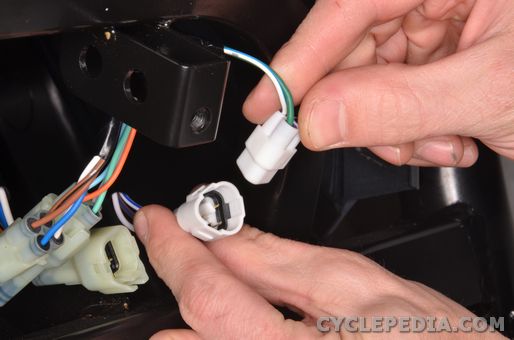

Disengage the lock on locking electrical connectors before attempting to unplug them.

Hold the connector body when connecting or disconnecting it. Do not pull the connector wire.

Check for faulty connector terminals. There shouldn’t be any bent, protruding or loose terminals.

Make sure the connector is plugged in completely. Make sure the connector locks correctly if a lock is present. Make sure there are not any loose wires.

Before connecting an electrical connector, check for damaged terminal cover or loose negative terminal.

Check the bullet connector cover for proper coverage and installation.

Join the terminals completely in bullet connectors. Check the cover for proper coverage. Do not make the cover opening face up.

Secure the wire harness so that it will not make contact with parts which will generate high heat.

Route wire harnesses to avoid sharp edges or corners. Avoid the projected ends of bolts and screws. Route wire harnesses passing through the side of bolts and screws.

After clamping, check each harness to make sure that it is not interfering with any moving or sliding parts.

Secure wire harnesses to the frame with the respective wire bands at the designated locations. Tighten the bands so that only the insulated surfaces contact the wire harnesses.

Route harnesses so they are neither pulled tight nor have excessive slack.

Protect wires and harnesses with electrical tape or tube if they contact a sharp edge or corner.

Make sure rubber wire grommets are installed correctly.

When a testing device is used, make sure to understand the operating methods thoroughly and operate according to the operating instructions.

Be careful not to drop any parts.

After clamping, check each wire to make sure it is secure.

Do not squeeze wires against the weld or its clamp.

Do not break the sheath of wire. If a wire or harness has a broken sheath, repair it by wrapping it with protective tape or replace it if needed.

When installing other parts, do not press or squeeze the wires.

After routing, check that the wire harnesses are not twisted or kinked.

Wire harnesses routed along with handlebar should not be pulled tight, have excessive slack or interfere with adjacent or surrounding parts in all steering positions.

When rust is found on a terminal, remove the rust with sand paper or equivalent before connecting.

VIN and Engine Number Location

The VIN stamped into the front right side of the frame.

The engine number is stamped into the back of the left crankcase half.

Information and Warning Sticker Locations

Specifications

General Specifications

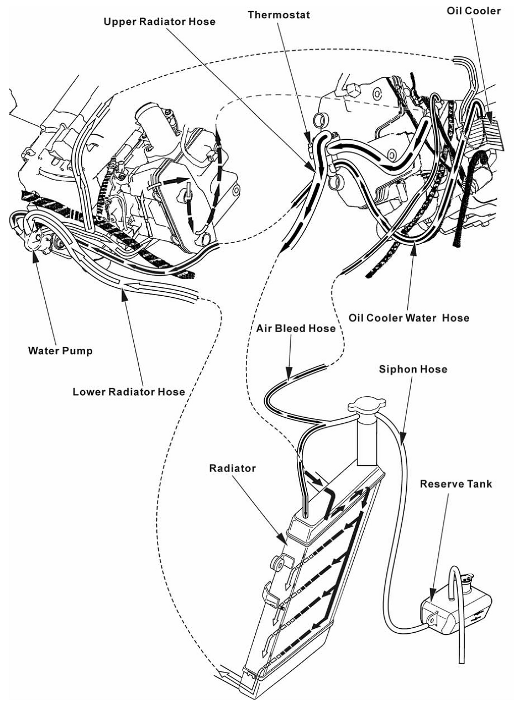

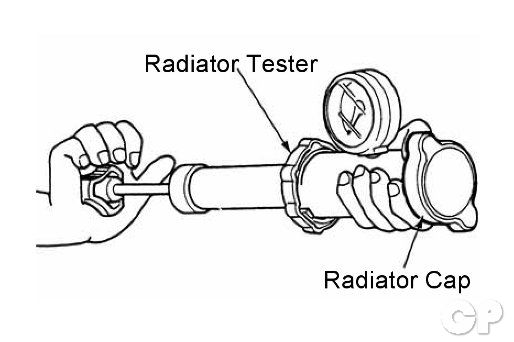

| Name & Type | Overall length | Overall width | Overall height | Wheel base | Engine type | Displacement | Fuel used | Front wheel | Rear wheel | Total | Front wheel | Rear wheel | Total | Front wheel | Rear wheel | Ground clearance | Min. turning radius | Starting system | Type | Cylinder arrangement | Combustion chamber type | Compression ratio | Compression pressure | Cooling type | Lubrication type | Oil pump type | Oil filter type | Oil capacity 700i | Air cleaner type & No | Fuel capacity | TYPE | VENTURE DIA | Type | Ignition timing | Spark plug | Spark plug gap | Battery | Clutch type | Clutch operation system | Primary reduction system | Secondary reduction system | High reduction ratio | Low reduction ratio | Reverse ratio | FR/RR tire rolling circumference | Tire pressure (person 75 kg) | Turning angle | Brake system type | Front | Rear | Suspension type | Front | Rear | Frame type | Oil capacity 700i | ITEM | Throttle cable free play | Fuel injector resistance (at 20°C/68°F) | Fuel pump standard pressure (at 80 L/Hr) | T-MAP sensor resistance (20°C) (1 and 2 pins) | Inductive ignition coil | Throttle position sensor (TPS) resistance (at 20°C/68°F) | Crank position sensor resistance | Item | Cylinder head compression pressure | Cylinder head warpage | Camshaft runout | Rocker arm to shaft clearance | Item | Item | I.D. | Warpage | Taper | Out-of-round | Piston O.D. | Piston O.D. measuring position | Piston-to-cylinder clearance | Piston pin hole I.D. | Piston pin O.D. | Piston-to-piston pin clearance | Connecting rod small end I.D. bore | Item | Connecting rod big end radial clearance | Runout | ITEM | Recommended engine oil | Oil pump rotor | Oil capacity 700i | ITEM | Coolant capacity | Radiator cap relief pressure | Begin to open | Fully open | Valve lift | Standard coolant concentration | COOLANT GRAVITY CHART | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Temperature °C | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| COOLANT MIXTURE (WITH ANTI-RUST AND ANTI-FREEZING EFFECTS) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Item | Tie rod length | Rod-end (tie rod) angle | Item | ITEM | Capacity | Current leakage | Charging coil resistance (20°C/68°F) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stator output current | Standard |

| 1300 rpm | 12.0 A Minimum |

| 5000 rpm | 22.0 A Minimum |

| 10000 rpm | 30.0 A Maximum |

| Item | Standard |

| Spark plug | NGK-CR7E |

| Spark plug gap | 0.6 – 0.7 mm (0.024 – 0.028 in.) |

| Ignition system | Full transistor digital ignition |

| Ignition timing | 5° / 1500 rpm |

Torque Specifications

Chassis Torque Specs

| TORQUE VALUES | Torque | ||

| kgf-m | |||

| 5 mm bolt, nut | |||

| 6 mm bolt, nut | |||

| 8 mm bolt, nut | |||

| 10 mm bolt, nut | |||

| 12 mm bolt, nut | |||

| 5 mm screw | |||

| 6 mm screw, SH bolt | |||

| 6 mm flange bolt, nut | |||

| 8 mm flange bolt, nut | |||

| 10 mm flange bolt, nut | |||

Diagnostic Trouble Codes (DTCs)

To evaluate the DTCs see the Check Engine Lamp (CELP) and Diagnostic Tool topics.

| Blinks | Failure Codes | Fault description | Priority | Fault management |

| 1 | P0217 | Engine temperature overheat | 1 | 1.Stop immediately and check CELP code. 2. Check if the engine temperature sensor or electric circuit is faulty. 3. Check engine lubrication and cooling systems. 4. Check engine ignition and fuel systems. |

| 2 | P0335 | Crankshaft position sensor or circuit malfunction | 2 | 1. Check if the crankshaft position sensor, its connector, or wiring is faulty. 2. Make sure the generator rotor is aligned with the crankshaft position sensor. |

| 3 | P1120 | Throttle position sensor setting value problem | 2 | 1.Check if the TPS connector or wiring is faulty. 2.Check if the TPS is adjusted. |

| 4 | P1121 | Throttle position sensor output range problem | 2 | 1. Make sure the TPS connector is connected correctly. 2. Inspect the TPS |

| Blinks | Failure Codes | Fault description | Priority | Fault management |

| 5 | P1122 | Throttle position sensor movement speed problem | 2 | 1. Make sure the TPS connector is connected correctly. 2. Inspect the TPS |

| 6 | P0560 | Battery voltage malfunction | 1 | 1. Check the battery voltage. 2. Inspect the charging system. |

| 7 | P0110 | Intake air temperature circuit malfunction | 2 | Inspect the T-MAP sensor |

| 8 | P0410 | Idle air valve circuit malfunction | 2 | 1. Check if the ISC connector or wiring is faulty. 2. Check the resistance of the idle air valve. |

| 9 | P0505 | Idle speed volume control range problem | 3 | 1.Check the ISC steps range with the diagnostic tool. 2. Check throttle body for carbon deposits. 3. Check intake for air leaks |

| 10 | P0251 | Injector or electric circuit problem | 2 | 1. Make sure the fuel injector connector is connected correctly. 2. Check if the ECU sends a signal to the injector. 3. Check the power source and resistance of the injector. 4. Make sure the battery is fully charged and connected correctly. |

| Blinks | Failure Codes | Fault description | Priority | Fault management |

| 11 | P0350 | Ignition coil or electric circuit malfunction | 2 | 1. Make sure the ignition coil connector is connected correctly. 2. Check if the ECU sends a signal to the ignition coil. 3. Check the ignition coil power source and resistance. 4. Make sure the battery is fully charged and connected correctly. |

| 12 | P0230 | Fuel pump relay or electric circuit malfunction | 2 | 1. Make sure the relay and pump connectors are connected correctly. 2. Check if the ECU sends a signal to relay. 3. Check the fuel pump relay resistance |

| 13 | P0219 | Engine speed has exceeded top speed | 2 | Check if the CVT belt is broken. |

| 14 | P1560 | Sensor doesn’t receive power source from ECU | 2 | 1. ECU output to each sensor should be 5 DCV. 2. Check if the power source for all sensors is 5 DCV. 3. Check for a problem in the wiring harness. 4. If the CELP still blinks replace the ECU with a new item even if the output power source of ECU is normal. |

| 15 | P0700 | Engine starting speed exceed CVT speed limited | 2 | Not used. |

| 16 | P0115 | Engine temperature sensor or electric circuit malfunction | 2 | 1. Make sure the WTS connector is connected correctly. 2. Check if the ECU pin is broken. 3. Check if the resistance of the sensor is out of specification. |

| 17 | P1561 | Temperature gauge electric circuit malfunction | 2 | Not used. |

| Blinks | Failure Codes | Fault description | Priority | Fault management |

| 18 | P0650 | CELP electric circuit malfunction | 3 | 1. Check if the CELP bulb is faulty. 2. Check the CELP wires for damage. |

| 21 | P0105 | Atmospheric Pressure Sensor/Circuit Malfunction | 2 | 1. Make sure the MAP sensor connector is connected correctly. 2. Check if the ECU pin is broken. 3. Check the sensor voltage. 4. Use Diagnostic Tool to check the pressure. |

| 22 | P0110 | Roll sensor or electric circuit malfunction | 2 | 1. Make sure the sensor is installed in the correct position. 2. Check the sensor voltage. 3. Check if the ECU pin is broken. |

Periodic Maintenance

Maintenance General Information

This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly overhaul work will be greatly reduced. This information applies to vehicles already in service as well as new vehicles that are being prepared for sale. All service technicians should be familiar with this entire chapter.

WARNING

- Before running the engine, make sure that the working area is well-ventilated. Never run the engine in a closed area. The exhaust contains poisonous carbon monoxide gas which may cause death to people.

- Gasoline is extremely flammable and is explosive under some conditions. The working area must be well-ventilated and do not smoke or allow flames or sparks near the working area or fuel storage area.

Periodic Maintenance Chart

Periodic maintenance is required to keep the vehicle safe and performing properly. For use exceeding the chart repeat the service intervals.

| EVERY | ||||

| WHICHEVER COMES FIRST | mi | |||

| Km | ||||

| ROUTINE | MONTH | |||

| Engine oil | •Replace (Warm engine before draining). | o | o | o |

| Oil strainer | •Clean. •Replace if necessary. | o | o | o |

| Engine oil filter cartridge | •Replace | o | o | o |

| Front drive gear oil | •Check oil level/oil leakage •Replace every 12 months. | o | o | |

| Rear drive gear oil | •Check oil level/oil leakage •Replace every 12 months, | o | o | |

| Air filter element (for engine) | •Clean. (More often in wet or dusty areas.) •Replace if necessary. | o | o | |

| Air filter element (for V-belt compartment) | •Clean. (More often in wet or dusty areas.) •Replace if necessary. | o | o | |

| Cylinder head cover breather system | •Check breather hose for cracks or damage. •Replace if necessary. | o | o | |

| Spark plug | •Check condition, •Adjust gap and clean. •Replace if necessary. | o | o | o |

| Fuel line | •Check fuel hose for cracks or damage. •Replace if necessary. | o | o | |

| Valves | •Check valve clearance, •Adjust if necessary. | o | o | o |

| Brake | •Check operation and brake fluid. •Replace brake pad if necessary. | o | o | o |

| Coolant | •Check coolant leakage. •Replace if necessary. •Replace coolant every 24 months. | o | o | o |

| V-belt | •Check operation. •Replace if damage or excessive wear. | o | o | |

| Exhaust system | •Check leakage. •Retighten if necessary. •Replace gasket if necessary. | o | o | |

| Spark arrester | •Clean | o | o | |

| Wheels | •Check balance/damage/runout. •Replace if necessary. | o | o | o |

| Wheel bearings | •Check bearing assembly for looseness/damage. •Replace if damaged. | o | o | o |

| Steering system | •Check operation. •Replace if damaged. •Check toe-in. •Adjust if necessary. | o | o | o |

| Drive shaft boots | •Check operation. •Replace if damaged. | o | o | |

| Suspension (front) | •Check operation. •Correct if necessary. | o | o | |

| Suspension (rear) | •Check operation. •Correct if necessary. | o | o | |

| Knuckle shafts/ Steering shaft | •Lubricate every 6 months. | o | o | |

| Fittings and Fasteners | •Check all chassis fittings and fasteners. •Correct if necessary. | o | o | o |

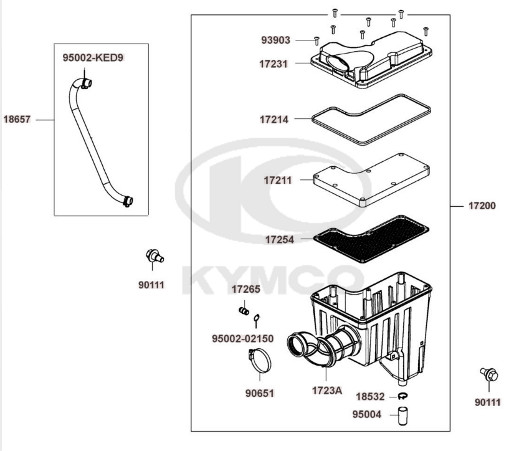

Air Filter Servicing

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

UXV700 Differences

Note the 700 model has a different shaped air filter. Clean, inspect, and oil the filter in the same manner.

Removal

Remove the seats. See the Seat topic for more information.

Remove the center cover. See the Center Cover topic for more information.

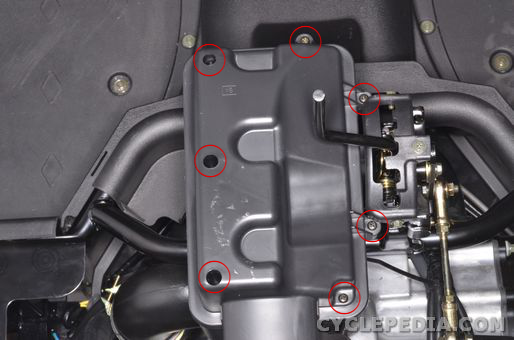

There are seven airbox cover screws.

Remove the airbox cover screws with a #2 Phillips screwdriver.

Remove the airbox cover.

Loosen the air filter clamp screw with a flat blade screwdriver or an 8 mm socket.

Lift out the air filter. Clean out the airbox.

Loosen the air filter holder screw with a #2 Phillips screwdriver. Remove the screw and washers from the air filter.

Remove the air filter holders from the air filter.

Slide out the air filter screen.

Separate the inner and outer air filter element pieces.

Servicing

Place the filter in a container and saturate it with a foam air filter cleaner both inside and out. Products like Simple Green, dish soap, or most non-flammable solvents will work if foam air filter cleaner is unavailable.

Let the filter soak for approximately 5 minutes – follow cleaning product instructions if different. Rinse the element in warm water until the water runs clear. You may squeeze the filter to remove excess cleaner but never twist it.

Let the air filter dry completely.

Once the element is completely dry, blow it off with low pressure compressed air or pat it down with a clean shop towel to remove any remaining debris.

NOTE: Always wear safety glasses when using compressed air and never point it directly at yourself or anyone else.

Oil the filter with foam air filter oil or fresh engine oil. Squeeze out any excess oil. The element should be wet with oil, but not to the point of dripping.

Clean the out the airbox.

Installation

Fit the inner air filter element into the outer element.

Insert the screen into the air filter elements.

Install the air filter holders into the air filter. The holders must fit together as shown.

Install the air filter holder screw and washers. Tighten the air filter holder screw securely with a #2 Phillips screwdriver.

Fit the air filter into place as shown.

Tighten the air filter clamp screw securely with a flat blade screwdriver or an 8 mm socket.

Fit the airbox cover into place.

Insert the seven airbox cover screws. Tighten the airbox cover screws securely with a #2 Phillips screwdriver.

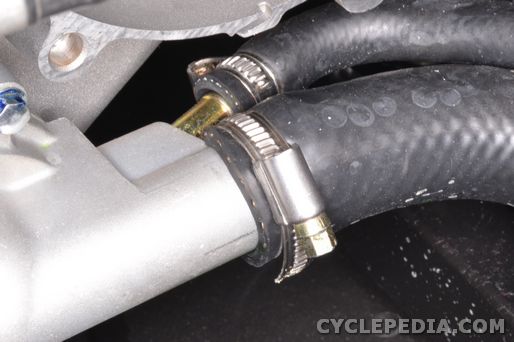

Inspect the airbox drain tube.

Remove the tube and drain away any fluid build up or debris that has collected. Return the tube and secure it with the clamp.

Install the center cover. See the Center Cover topic for more information.

Install the seats. See the Seat topic for more information.

Brake Fluid

The KYMCO UXV 500/700 uses DOT 4 brake fluid. Do not mix the brake fluid types. The system should be bled whenever the brakes feel spongy, or if the brake system has been taken apart and rebuilt. Always use fresh brake fluid from a tightly sealed container.

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Warning: Brake fluid is very caustic and can damage paint, chrome and plastic. Wipe up any spills immediately.

Inspection

Place the vehicle on level ground. Turn the steering wheel so that the front tires are straight.

Open the hood. See the Hood topic for more information.

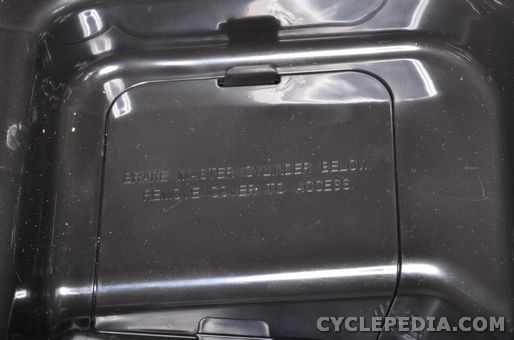

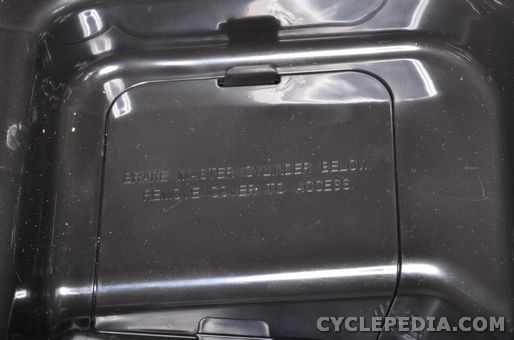

Remove the brake fluid panel at the bottom of the front cargo box.

Unscrew the master cylinder cap. Make sure the brake fluid level is acceptable.

Draining

Lift the hood. See the Hood topic for more information.

Remove the front cargo box. See the Hood topic for more information.

Place a suitable container under the master cylinder to catch the fluid. Remove the brake fluid drain bolt to drain the brake fluid.

Note: Do not splash brake fluid onto any rubber, plastic and coated parts. When working with brake fluid, use shop

towels to cover these parts.

Note: The front and rear brakes follow the same procedure.

Crack open the bleeder valve on the brake caliper using an 8 mm wrench. This valve is usually very tight so use a box end wrench or a 6 point socket and ratchet to prevent rounding off the head. Snug the bleeder valve back down.

Place a length of 6 mm inside diameter clear hose on the bleeder valve and place the other end in a container to catch the old brake fluid.

Open the bleeder valve and pump the brake pedal to remove the brake fluid. Stop pumping the pedal when the fluid stops flowing.

Alternatively, you can use a Mighty -Vac or a similar device to suck out the old brake fluid.

Bleeding

When bleeding the brakes start from the farthest caliper and work towards the master cylinder.

Fill the master cylinder with DOT 4 brake fluid from a fresh, newly opened container and bleed the brakes.

Note: The front and rear brakes follow the same procedure.

Pull off the rubber cap over the bleeder valve on the caliper you are working on.

Crack open the bleeder valve on the brake caliper using an 8 mm wrench. This valve is usually very tight so use a box end wrench or a 6 point socket and ratchet to prevent rounding off the head. Snug the bleeder valve back down.

Place a length of 6 mm inside diameter clear hose on the bleeder valve and place the other end in a container.

Pump the brake pedal several times and hold the pedal down. While holding the pedal, crack open the bleeder valve. The brake pedal will travel all the way to the floor and brake fluid and/or air will come out of the bleeder valve into the 6 mm hose. Tighten the bleeder valve before releasing the brake pedal. Pump the pedal several times again and repeat the process.

Be certain to check the master cylinder reservoir occasionally to make sure the reservoir doesn’t run dry. Add more brake fluid as necessary. Continue this process until clean brake fluid comes out of the bleeder valve and there are no air bubbles. The brake pedal should feel firm.

Tighten the bleeder valves to specification and push their rubber covers over the nipples.

| Item | Kgf-m | N-m |

| Bleeder valves |

Make sure the reservoir has the proper amount of fluid.

Install the master cylinder cap.

Check the function of the brakes before operating the machine.

Brake Inspection

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Master Cylinder

Place the vehicle on level ground so the front master cylinder reservoir is level.

Lift the hood. See the Hood topic for more information.

Remove the brake fluid panel at the bottom of the front cargo box.

Check the level of brake fluid.

Front Pads and Rotors

Use a jack to raise the front wheels off the ground. Be sure it is on a level surface.

Remove the front wheels. See the Wheels and Wheel Hubs topic for more information.

Inspect the pad linings and rotors.

Replace the pads if they are worn to the limit line. Replace the rotors if they are not within specification.To replace the front brake pads and/or rotors see the Front Caliper and/or Front Disc Brake topic.

Install the front wheels. See the Wheels and Wheel Hubs topic for more information.

Rear Brake Pads and Rotors

Use a jack to raise the rear wheels off the ground. Be sure it is on a level surface.

Remove the rear wheels. See the Wheels and Wheel Hubs topic for more information.

Inspect the pad linings and rotor.

Replace the pads if they are worn to the limit line.

Replace the rotor if it is damaged or out of specification.

To replace the front brake pads and/or rotors see the Rear Brake Caliper and/or Rear Brake Disc topic.

Install the front wheels. See the Wheels and Wheel Hubs topic for more information.

Parking Brake

Measure the brake cable end length “L” and check it against the specification. See the Rear Parking Brake Adjustment topic for more information.

Compression Test

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Run the engine to warm it up before conducting a compression test. Make sure your compression gauge is in good working order and does not leak.

Remove the center cover. See the Center Cover topic for more information.

Remove the spark plug. See the Spark Plug topic for more information.

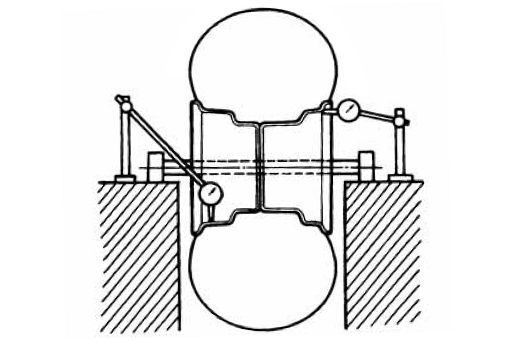

Install the compression tester into the sparkplug hole using a compression gauge adapter and tighten it hand tight.

Hold the throttle wide open and use the electric starter to turn the engine over. Crank the engine until the needle on your compression gauge stops rising. This should occur in 4 to 7 seconds of engine cranking. Do not crank the engine for more than 7 seconds. Compare your reading with specification.

| Cylinder head compression pressure | 15 kg/cm2(1500 kPa, 213 psi) | |

Low compression is an indication of excessive engine wear, possibly worn rings or poorly sealing valves, or improper valve clearance.

High compression is possibly an indication of excessive carbon buildup on the piston or performance modifications.

Engine Oil

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Type and Capacity

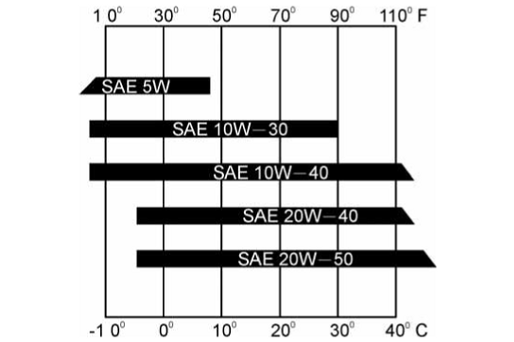

Recommended engine oil: KYMCO 4-stroke oil or equivalent motor oil API service classification SJ Viscosity: SAE 5W-50

Other engine oil viscosities shown in the chart may be used when the average temperature in the riding area is within the indicated range.

2.4 L (oil change)

2.6 L (oil and filter change)

2.9 L (total)

Caution: Any oil used in place of the recommended oil could cause serious engine damage. Do not use oils which contain graphite or molybdenum additives. These oils can adversely affect clutch operation. Also, not recommended are racing, vegetable, non-detergent, and castor-based oils.

Inspection

Start the engine and let it warm up for 2 – 3 minutes. Park the vehicle on a level surface. Stop the engine and allow the oil to settle for 2 – 3 minutes.

Inspect the oil level through the sight glass. The sight glass is located on the left side of the engine. The oil level should be between the “H” and “L” marks as shown.

If the oil level is at or below the “L” mark add more of the same type and brand of oil to the engine through the oil filler hole. Wipe down the area around the filler cap to prevent debris from entering the engine. Inspect the filler cap O-ring and replace it as needed.

If the oil level is above the upper mark drain some of oil from the drain plug.

Servicing

Remove the seats. See the Seat topic for more information.

Remove the center cover. See the Center Cover topic for more information.

Start and run the engine for a minute or two, this will heat the engine and allow the oil to drain out faster and more completely.

NOTE: Hot engine oil can burn you, take precautions not to touch the oil when draining.

Place a drain pan under the oil filter cap and drain plug. Loosen the oil filter cap with a 17 mm socket.

Remove the drain plug, oil filter cap, strainer, spring and O-ring. Allow the oil to drain into the pan. Clean and inspect the strainer. Inspect the O-ring. Replace any parts if needed.

Remove the oil cap for faster draining.

Use a special oil filter wrench to remove the oil filter cartridge.

Special Tool- Oil Cartridge Wrench: A120E00061

Remove the oil filter and the rubber oil filter seal from the engine case.

Apply engine oil to the O-ring. When the oil has finished draining install the oil filter cap, strainer, spring and O-ring. Torque the oil filter cap to specification with a 17 mm socket.

Note: You can remove the drain plug to drain the engine oil also, but you will not be able to clean the strainer. This is a good way to drain engine oil if it was over-filled. Replace the sealing washer with a new item if it was removed.

| Item | Torque kgf-m (N-m, ft-lb) | Remarks |

| Engine oil filter cap | 1.5 (15, 11) | Apply oil |

| Engine drain plug |

Apply fresh engine oil to the rubber oil filter seal.

Install the oil filter onto the engine and tighten by hand until the oil filter contacts the engine.

Tighten the oil filter with the special oil filter wrench to specification.

Special Tool- Oil Cartridge Wrench: A120E00061

| Item | Torque kgf-m (N-m, ft-lb) | Remarks |

| Engine oil filter cartridge | 1 (10, 7.2) | Apply oil |

Refilling

Add the proper type and quantity of oil and install the oil filler cap. Start the engine and let it run for several minutes. Check for any oil leaks. Check the oil level as describe above. If the oil level is too high drain the excess oil from the oil drain bolt.

2.4 L (oil change)

2.6 L (oil and filter change)

2.9 L (total)

Install the center cover. See the Center Cover topic for more information.

Install the seats. See the Seat topic for more information.

Final Drive Oil

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Drive the vehicle until the rear drive gear oil is warm. Place the vehicle on a level surface.

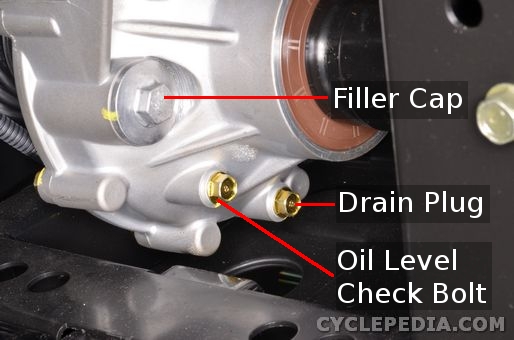

Rear Drive Gear Oil

Draining

Place a suitable oil drain pan under the rear differential.

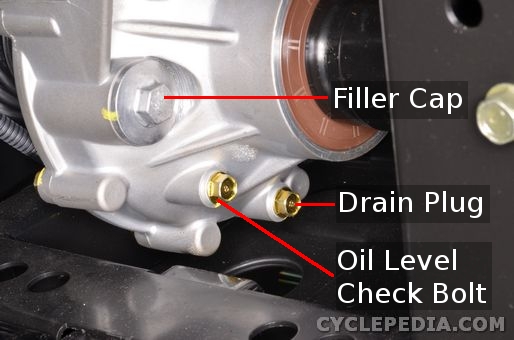

Remove the filler cap with a 17 mm socket.

Inspect the filler cap O-ring and replace if needed.

Remove the drain plug with a 12 mm socket and allow the oil to completely drain.

Filling

Install a new sealing washer and the drain plug. Tighten the drain plug to specification with a 12 mm socket.

| Item | N-m | kgf-m |

| Rear drive drain plug |

Add the specified type and amount of gear oil into the filler hole.

| Type | Capacity |

| SAE 80~90 hypoid gear oil | 250 cc (8.45 US oz) |

Remove the oil level check bolt and sealing washer with a 12 mm socket. Check that the oil level reaches the oil level check hole.

Install the filler cap and O-ring. Tighten it to specification with a 17 mm socket.

| Item | N-m | kgf-m |

| Rear drive filler cap |

Install the oil level check bolt with a new sealing washer and tighten to specification using a 12 mm socket .

| Item | N-m | kgf-m |

| Oil level check bolt |

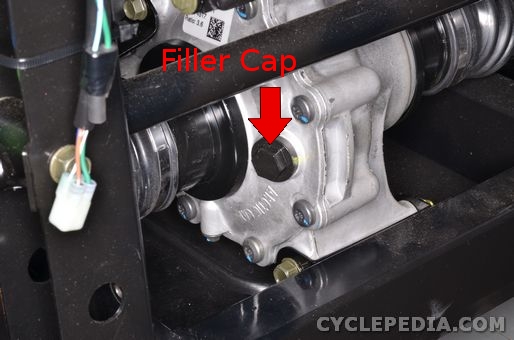

Front Drive Gear Oil

Draining

Remove the front skid plate. See the Skid Plates topic for more information.

Place a suitable oil drain pan under the rear differential.

Remove the filler cap with a 17 mm socket.

Inspect the filler cap O-ring and replace if needed.

Remove the drain plug with an 8 mm socket and allow the oil to completely drain.

Filling

Install a new sealing washer and the drain plug. Tighten the drain plug to specification with an 8 mm socket.

| Item | N-m | kgf-m |

| Front drive drain plug |

Add the specified type and amount of gear oil into the filler hole.

| Type | Capacity |

| SAE 80~90 hypoid gear oil | 270 cc (9.13 US oz) |

Install the filler cap and O-ring. Tighten it to specification with a 17 mm socket.

| Item | N-m | kgf-m |

| Rear drive filler cap |

Install the front skid plate. See the Skid Plates topic for more information.

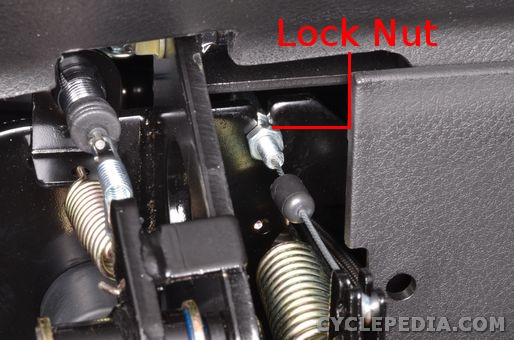

Rear Parking Brake Adjustment

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Make sure the parking brake doesn’t drag when the lever is released, and the parking brake holds when the lever is applied. Adjust the inline cable adjuster as needed.

Trace the cable up fro the parking brake until you reach the adjuster. Loosen the adjuster lock nut with a 10 mm wrench. Turn the adjuster out to decrease free-play and turn it in to increase free-play. Always check that the parking brake operates properly.

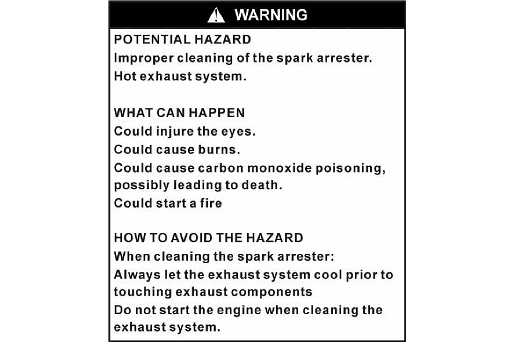

Spark Arrestor

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Note: Always allow the exhaust system plenty of time to cool before touching it.

Remove the three arrestor bolts with an 8 mm socket.

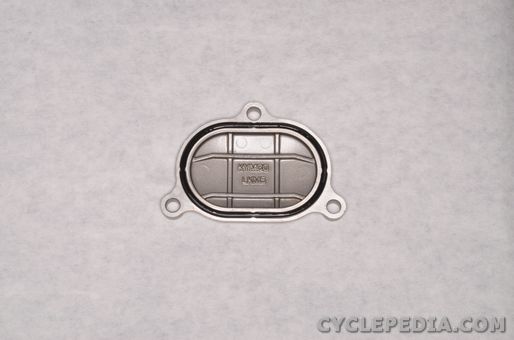

Remove the spark arrestor and gasket.

Clean the carbon off of the spark arrestor screen with a wire brush.

Inspect the spark arrestor screen for any damage and replace as needed.

Installation

Install the spark arrestor with a new gasket.

Install the spark arrestor bolts and tighten them securely with an 8 mm socket.

Spark Plug

| Item | Standard |

| Spark plug | NGK-CR7E |

| Spark plug gap | 0.6 – 0.7 mm (0.024 – 0.028 in.) |

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Remove the center cover. See the Center Cover topic for more information.

Pull the spark plug cap off of the spark plug.

Clean off the area surrounding with compressed air or a shop towel to make sure debris doesn’t get into the combustion chamber when the spark plug is removed.

NOTE: Always wear safety glasses when using compressed air and never point it directly at yourself or anyone else.

Remove the spark plug using a 5/8 in deep well spark plug socket.

Inspection

Inspect the spark plug for signs of damage. Always replace a spark plug if any part of it is damaged.

The color of the spark plug’s porcelain tip can indicate how the mixture is burning. A white colored plug shows a lean mixture, where a dark plug shows a rich mixture. A light brown color is optimal. For more information see the spark plug trouble shooting chart.

https://www.cyclepedia.com/spark-plug-troubleshooting/

If the plug is dirty or has carbon build up it can be cleaned with small wire brush. Do not hesitate to replace a spark plug.

Always check the gap of the spark plugs before installation. If the gap needs to be adjusted bend the ground electrode carefully.

| Item | Standard |

| Spark plug gap | 0.6 – 0.7 mm (0.024 – 0.028 in.) |

Installation

Install the spark plug by hand. Tighten it to specification a 5/8 in deep well spark plug socket.

| Item | Torque kgf-m (N-m, ft-lb) |

| Spark plug |

Do not over tighten the spark plug. The cylinder head is made out of soft metal, and it can be easily damaged.

Install the spark plug cap onto the spark plug.

Install the center cover. See the Center Cover topic for more information.

Throttle Free Play

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Inspection

Inspect the throttle free play by operating the throttle pedal. The end of the throttle pedal should travel 3 – 5 mm (0.12 – 0.20 in) before the cable slack is taken up and the throttle begins to open.

When the throttle pedal is pushed all the way in and released it should return to its resting position quickly. Also, the throttle operation should be smooth.

Adjustment

First Step

Remove the pedal cover. See the Pedal Cover topic for more information.

Loosen the lock nut with a 10 mm wrench.

Adjust the adjuster nut on the other side with a 10 mm wrench until the free play is within specification. Tighten the lock nut when finished. Proceed to the second step if the correct free play can not achieved.

Second Step

Slide back the rubber cover from the throttle cable.

To adjust the throttle free play loosen the lock nut on the throttle cable with an 8 mm wrench and turn the adjuster with an 8 mm wrench. Turn the adjuster out to decrease free-play and turn it in to increase free-play. Always check that the throttle operates freely and returns properly. Tighten the lock nut securely.

Install the pedal cover. See the Pedal Cover topic for more information.

Tires

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Tire Size

| Tire Tread Depth Service Limit | ||||

| Front Tire | Rear Tire | 4 mm (0.16 in) | ||

Directional Rotation

Check the “ROTATION” arrow on the tire’s sidewall.The arrow indicates the direction in which the tire should turn going forward.

Toe-In Adjustment

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Inspection

Check that all tires are properly inflated at the same pressure. See the Tires topic for more information.

Mark the center of both front tire treads.

Raise the front tires off the ground.

Straighten the front wheels on a level surface.

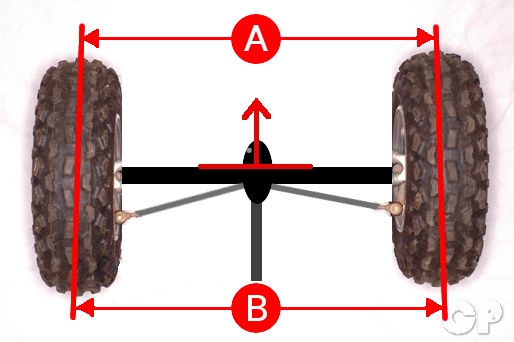

Measure the distances between the center of the tires with a toe-in-gauge on the front of the tires. Call this measurement A. Rotate the tires 180°. Measure the distances between the center of the tires with a toe-in-gauge on the rear of the front tires. Call the rear measurement B.

The toe-in measurement = B – A.

The toe-in should be 0 – 15 mm (0 – 0.6 in).

Adjustment

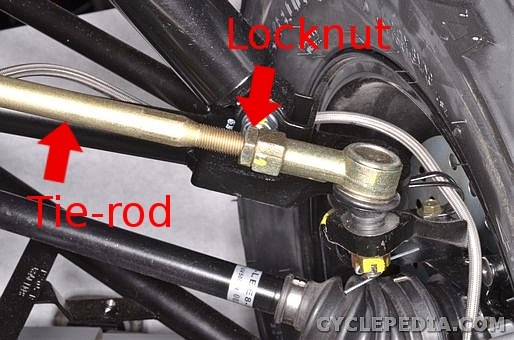

Mark the tie-rods for reference.

Loosen the left and right outer tie-rod locknuts with a 19 mm wrench. Hold the tie-rod end and turn the tie-rod. Turn both the tie-rods evenly until the toe-in is within specification. Moving the tie-rods out towards the wheels will increase toe-in. Moving the tie-rods towards the center will decrease toe-out. Temporarily tighten the tie-rod locknuts with a wrench and re-check the toe in.

The toe-in should be 0 – 15 mm (0 – 0.6 in).

Tighten the tie-rod locknuts to specification with a 19 mm wrench.

| Item | N-m | Kgf-m |

| Tie-rod end locknuts |

After adjusting the toe-in take the machine for a slow test ride. If the machine pulls to the left or right when the steering wheel is facing straight ahead the toe-in needs to be readjusted more evenly.

Valve Adjustment

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Inspection

The engine has to be cold (room temperature) to check the valve clearance.

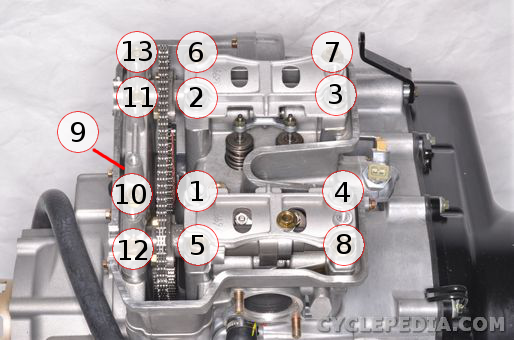

| Remove these components | |

| TORQUE VALUES | |

| N-m | |

| TAPPET ADJ. NUT | M5 x 0.5 |

Assembly

Make sure the valve adjuster cover O-rings are in good condition. Apply a light coat of fresh engine oil to the O-rings. Fit the valve adjuster covers into place.

Install the valve adjuster cover bolts. Tighten the bolts securely with an 8 mm socket.

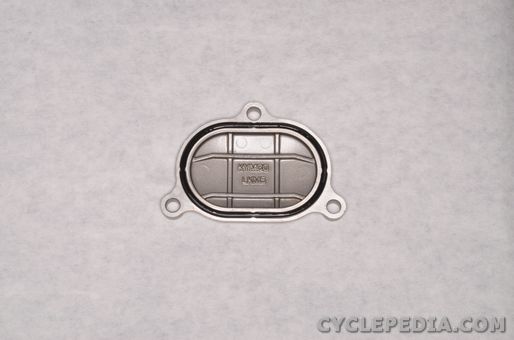

Make sure the crankshaft cap O-ring is in good condition. Apply fresh engine oil to the O-ring.

Install the crankshaft cap.

Tighten the crankshaft cap securely with a 10 mm Allen socket. Do not over tighten this cap.

Make sure the timing plug O-ring is in good condition. Apply fresh engine oil to the O-ring.

Install the timing inspection plug and tighten it securely with a large flat blade screwdriver.

External Components

GENERAL INSTRUCTIONS

TROUBLESHOOTING

Noisy exhaust muffler

Lack of power

Trim Clips

Screw Type

Back the screw out with a Phillips screwdriver to unlock the screw type trim clips. Install the trim clip and then turn in the screw to lock the clip in place.

Button Type

Depress the head of trim clip center piece (1). Pull out the trim clips.

Let the center piece stick out toward the head so that the pawls (2) close. Insert the trim clip into the installation hole. To prevent the pawl (2) from damage, insert the fastener all the way into the installation hole.

Push in the head of center piece until it becomes flush with the trim clip outside face.

Boot Guard

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Note: The right and left side boot guards follow the same removal/installation procedure.

Remove the boot guard mounting bolt with a 10 mm socket.

Remove the boot guard.

Installation

Install the boot guard.

Install the boot guard mounting bolt and tighten it securely with a 10 mm socket.

Canopy Bars

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

The headrests are mounted to the canopy bars with three #3 Phillips screws. Note, some headrest may be mounted with Allen screws.

Remove the upper seatbelt covers.

Remove the upper seatbelt mounting bolts and nuts with a 17 mm socket.

There are two upper crossbars. Support the bars as you remove the bolts. Remove the upper crossbar bolts with a 12 mm socket.

Remove the upper crossbars.

Remove the eight headrest cross tube bolts with a 12 mm socket. Remove the headrest cross tube.

Support the canopy bars. Loosen the bolts with an 8 mm Allen. Remove the four nuts and bolts for each canopy bar. Remove the canopy bars.

Installation

Install the canopy bars. Install the nuts and bolts as shown. Tighten the bolts to specification with an 8 mm Allen.

| Item | Torque Kgf-m (N-m, lbf-ft) |

| Canopy Bar Bolts |

Install the headrest cross tube. Install the eight headrest cross tube bolts and tighten them to specification with a 12 mm socket.

| Item | Torque Kgf-m (N-m, lbf-ft) |

| Cross tube bolts |

Install the two upper crossbars.

Install the eight headrest crossbar bolts and tighten them to specification with a 12 mm socket.

| Item | Torque Kgf-m (N-m, lbf-ft) |

| Crossbar bolts |

Install the upper seatbelt mounting bolts and nuts. Tighten the fasteners to specification with a 17 mm socket.

| Item | Torque Kgf-m (N-m, lbf-ft) |

| Seatbelt nuts and bolts |

Install the upper seat belt covers.

Install the headrests and tighten the fasteners securely.

Cargo Bed

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Release the latch and lift up the bed.

Unplug the taillight connectors. There is one for each side.

Remove the lift assist strut nuts with a 12 mm socket. Free the left and right lift assist struts from the bed.

With the help of an assistant support the bed in the closed position. Remove the locking clips and washers. Slide out the hinge pins. Lift off the bed with the help of an assistant.

Inspection

Check the rubber dampers for wear and damage.

Check the latching mechanism for damage.

Check the tailgate cables for wear and damage.

Disassembly

Tie-Downs

To remove the tie-down anchors loosen the nuts and bolts with a 10 mm socket. Remove the nuts, washers, bolts, and tie-down anchors.

Wheel Wells

To remove the wheel well take out the seven bolts with a 10 mm socket.

To remove the rear fenders and taillights see the Rear Fenders topic for more information.

Installation

Wheel Wells

Install the wheel wells. Install the seven bolts with a 10 mm socket.

Tie-Downs

Fit the tie-down anchors into place.

Install the bolts, washers, and nuts. Tighten the fasteners securely with a 10 mm socket.

Cargo Bed

Fit the cargo bed into place with the help of an assistant.

Slide in the hinge pins with the bed in the closed position. Install the washers and locking clips.

Connect the two left and right lift assist struts to the bed.

Hold the lift assist strut with a 12 mm wrench and tighten the nut securely with a 12 mm socket.

Plug in the taillight connectors. There is one for each side.

Close the cargo bed.

Make sure the latch closes correctly.

Center Cover

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Remove the seats. See the Seat topic for more information.

Remove the gearshift lever knob bolt with a 4 mm Allen, and lift off the knob.

Remove the two trim clips from the front of the center cover cover.

Lift up on the back of the center cover cover and free the posts from the frame.

Lift off the center cover cover.

Installation

Lower the center cover cover into place.

Guide the shift lever through the cover.

Fit the posts at the rear of the cover into the holes in the frame.

Install the two trim clips at the front of the center cover cover.

Fit the shift knob into place.

Install the gearshift lever knob bolt and tighten it securely with a 4 mm Allen.

Install the seats. See the Seat topic for more information.

Exhaust System

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Always allow the exhaust system plenty of time to cool before touching it.

Removal

Muffler

Loosen the muffler clamp pipe with a 6 mm Allen socket.

Remove the two muffler mounting bolts and washers with a 14 mm socket.

Slide off the muffler and gasket.

Exhaust Pipe

Remove the center cover. See the Center Cover topic for more information

Remove the heat shield panel bolts with a 14 mm socket.

Remove the heat shield panel.

Remove the floor panel bolts with a 14 mm socket.

Remove the floor panel.

Remove the exhaust pipe mounting nut with a 14 mm socket.

Remove the two header pipe joint nuts with a 12 mm socket.

Remove the header pipe.

Remove the exhaust gasket from the cylinder head.

Installation

Exhaust Pipe

Install a new exhaust gasket into the exhaust port. A small dab of grease will help hold tit in place, just be aware that it will smoke and burn off when the engine is started.

Fit the header pipe into place.

Thread on the header pipe joint nuts. Tighten them securely with a 12 mm socket.

Install the exhaust pipe mounting nut and tighten it to specification with a 14 mm socket.

| Item | N-m | kgf-m |

| Exhaust pipe mounting bolt |

Install the floor panel.

Install the floor panel bolts and tighten them securely with a 14 mm socket.

Install the heat shield panel.

Install the heat shield panel bolts and tighten them securely with a 14 mm socket.

Install the center cover. See the Center Cover topic for more information

Muffler

Slide on the muffler and gasket.

Install the two muffler mounting bolts and washers. Tighten them to specification with a 14 mm socket.

| Item | N-m | kgf-m |

| Exhaust muffler mounting bolt |

Tighten the muffler clamp pipe bolt to specification with a 6 mm socket.

| Item | N-m | kgf-m |

| Muffler clamp pipe bolt |

Floor Covers

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Remove the side covers. See the Side Covers topic for more information.

Remove the seats. See the Seat topic for more information.

Remove the center cover. See the Center Cover topic for more information.

Remove the under seat frame covers. See the Frame Covers topic for more information.

Remove the plate pedal. See the Pedal Cover topic for more information.

Tunnel Cover

Passenger side; Remove the two trim clips with a #2 Phillips screwdriver and the two bolts with an 8 mm socket.

Driver side; Remove the two trim clips with a #2 Phillips screwdriver and the two bolts with an 8 mm socket.

Remove the tunnel cover.

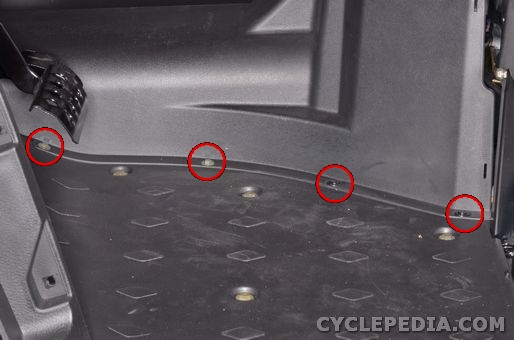

Floor Covers

Remove the right and left floor covers in the same manner. Remove the right cover first as it overlaps the left cover.

Remove the bolts along the side and bottom of the floor cover with a 10 mm socket.

Remove the bolts from the front of the floor cover where it meets the instrument and driver side covers with an 8 mm socket.

Remove the floor cover.

Installation

Floor Covers

Install the left side floor cover first.

Install the right side floor cover.

Install the bolts that connect the front of the floor cover to the instrument and driver side covers. Tighten the bolts securely with an 8 mm socket.

Install the bolts along the side and bottom of the floor cover and tighten them securely with a 10 mm socket.

Tunnel Cover

Install the tunnel cover.

On both sides install the two trim clips and the two bolts. Tighten the bolts securley with an 8 mm socket.

Install the plate pedal. See the Pedal Cover topic for more information.

Install the frame covers. See the Frame Covers topic for more information.

Install the center cover. See the Center Cover topic for more information.

Install the seats. See the Seat topic for more information.

Install the side covers. See the Side Covers topic for more information.

Frame Covers

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Remove the side covers. See the Side Covers topic for more information.

Remove the seat/s. See the Seat topic for more information.

Under Seat Frame Covers

Remove the under seat frame cover trim clips with a #2 Phillips screwdriver.

Remove the under seat frame cover.

Remove the tank cover screws with a Phillips screwdriver.

Lift up on the under seat frame cover to free the tabs from the tunnel cover.

Remove the remove the under seat frame cover. Remove the right and left under seat frame covers in the same manner.

Behind the Seat Frame Covers

Right

The right behind the seat frame cover is held in place by one bolt and four trim clips.

Remove the bolt with a 10 mm socket.

Remove the two bottom trim clips with a #2 Phillips screwdriver.

Remove the two inner trim clips with a #2 Phillips screwdriver.

Move the right behind the seat frame cover back and remove it from the vehicle.

Left

Free the final drive gear hose from the frame cover.

The left behind the seat frame cover is held in place by seven trim clips and a bolt.

The left behind the seat frame cover is attached to the CVT cooling duct. Remove the three trim clip fasteners with a #2 Phillips screwdriver.

Remove the two inner and two lower trim clips with a #2 Phillips screwdriver.

Remove the bolt with a 10 mm socket.

Lift out the left behind the seat frame cover.

Installation

Left

Fit the left behind the seat frame cover into place.

Install the two inner and two lower trim clips with a #2 Phillips screwdriver.

Install the three CVT cooling duct trim clip fasteners with a #2 Phillips screwdriver.

Install the bolt and tighten it securely with a 10 mm socket.

Route the final gear case breather hose through its guide on the cover.

Right

Fit the right behind the seat frame cover into place.

Install the two inner trim clips with a #2 Phillips screwdriver.

Install the two bottom trim clips with a #2 Phillips screwdriver.

Install the bolt and tighten it securely with a 10 mm socket.

Install the side covers. See the Side Covers topic for more information.

Install the seat/s. See the Seat topic for more information.

Front Bumper

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Front Bumper Cover

The front bumper cover is held on with four mounting bolts.

Remove the four front bumper cover bolts with a 10 mm socket.

Remove the front bumper cover.

Front Bumper

On the winch equipped LE models disconnect the winch leads.

The front bumper is mounted to the frame with four bolts and nuts on the inside of the frame rail.

Support the front bumper. Remove the nuts and bolts with a 14 mm socket.

Remove the front bumper from the frame.

Installation

Front Bumper

Fit the front bumper into place.

Install the four front bumper mounting nuts and bolts. Tighten them securely with a 14 mm socket.

Connect the leads to the winch on the LE models.

Front Bumper Cover

Fit the front bumper cover into place. If there is a winch make sure to position the end of the cable as shown.

Install the four front bumper cover mounting bolts and tighten them securely with a 10 mm socket.

Headlight

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Bulb Replacement

See the Lights topic.

Adjustment

Turn on the headlight switch. Adjust the headlight aim by turning the headlight aim adjustment screws with a #2 Phillips screwdriver or an 8 mm socket.

Removal

To replace the headlight bulb see the Lights topic for more information.

Remove the hood. See the Hood topic for more information.

Disconnect the headlight connectors if necessary.

Remove the headlight assembly mounting bolts with a socket.

Remove the headlight assembly mounting screw with a #2 Phillips.

Remove the headlight assembly.

Installation

Install the headlight assembly.

Install the headlight assembly mounting screw and tighten them securely with a #2 Phillips.

Install the headlight assembly mounting bolts and tighten securely with a socket.

Connect the headlight connectors if they were unplugged.

Hood

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Lift

There is a rubber retaining strap on each side of the hood.

Free the retaining straps from each side.

Lift up on the back of the hood and free the hood post from the grommet. Pivot the hood forward.

Removal

Unplug the headlight connectors.

Remove the cotter pins and washers from the hood pivot pins.

Slide the hood pivot pins out

Lift off the hood.

To remove the pivot bracket take out the three bolts and washers with a 10 mm socket.

To remove the headlights see the Headlight topic.

Front Cargo Box

There are four bolts that hold the front cargo box in place.

Remove the four front cargo box bolts with a 10 mm socket.

Lift out the front cargo box.

Installation

Front Cargo Box

Fit the front cargo box into place.

Install the four front cargo box bolts and tighten them securely with a 10 mm socket.

Hood

Fit the pivot bracket onto the hood. Install the three bolts and washers. Tighten the three bolts securely with a 10 mm socket.

Position the hood in place. Line up the pivot bracket with the frame.

Insert the pivot pins from the outside.

Install the washer on the inside of the pivot pin. Secure the washer and pin with a new cotter pin.

Plug in the two headlight connectors.

Close the hood and guide the pin into the grommet.

Guide the tabs on the side of the hood into place.

Secure the hood with the rubber retaining straps on each side.

Instrument Cover

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Lift the hood. See the Hood topic for more information.

Remove the steering wheel. See the Steering Wheel topic for more information.

Remove the seats. See the Seat topic for more information.

Remove the center cover. See the Center Cover topic for more information.

Remove the frame covers. See the Frame Covers topic for more information.

Remove the floor covers. See the Floor Covers topic for more information.

Remove the four mounting bolts with a 10 mm socket.

Disconnect the remote winch switch.

Disconnect the 12 volt accessory leads.

Disconnect the regulator winch switch.

Disconnect the display meter harness.

Disconnect the ignition switch.

Remove the nut from the “DIFF LOCK” lever. Leave the lever as shown.

Disconnect the dimmer switch.

Disconnect the 2WD/4WD switch.

Remove the instrument cover.

Remove the fasteners to separate the dash from the instrument panel.

Installation

Install the instrument cover.

Connect the 2wd/4wd switch.

Connect the dimmer switch.

Install the nut onto the “DIFF LOCK” lever. Adjust if necessary. See the Front Differential Removal and Installation topic for more information.

Connect the ignition switch.

Connect the display meter harness.

Connect the regulator winch switch.

Connect the 12 volt accessory leads.

Connect the remote winch switch.

Install the four mounting bolts and tighten securely with a 10 mm socket.

Install the floor covers. See the Floor Covers topic for more information.

Install the frame covers. See the Frame Covers topic for more information.

Install the center cover. See the Center Cover topic for more information.

Install the seats. See the Seat topic for more information.

Install the steering wheel. See the Steering Wheel topic for more information.

Close the hood. See the Hood topic for more information.

Pedal Cover

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Use a #2 Phillips screwdriver to push in the center of the push pin until it pops up.

Remove the push pins.

Remove the pedal cover.

Installation

Install the pedal cover.

Install the push pins.

Use a #2 Phillips screwdriver to push in the center of the push pin until it locks.

Fender Removal

The rear fenders mount to the sides of the cargo bed.

Unplug the taillight connectors. There is one for each side.

Loosen the nuts and bolts with a 10 mm socket. Remove the nuts, washers, bolts, and tie-down anchors.

Remove the trim clips from the top of the rear fender.

Remove the bottom trim clip.

Lift off the rear fender and make sure it clears the latch handle.

Taillights

Bulb Replacement

Turn the bulb sockets and free them from the housing.

Push in and turn counterclockwise to release the bulbs. Replace the bulbs as needed.

Insert the bulb sockets with the tabs aligned with the cutouts and rotate them to lock them into place.

Removal

Remove the three taillight mounting screws with a #2 Phillips screwdriver.

Remove the taillight from the inside of the fender.

Installation

Fit the taillight into the rear fender from inside the rear fender.

Install the taillight mounting screws and tighten them securely with a #2 Phillips screwdriver.

Fender Installation

Fit the rear fender/s into place.

Install the bottom trim clip.

Install the top trim clips.

Fit the tie-down anchors into place.

Install the bolts, washers, and nuts. Tighten the fasteners securely with a 10 mm socket.

Plug in the taillight connectors. There is one for each side.

Seat

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

The release lever for the seat is located under the front of the seat.

Pull up on the seat release and lift up on the front of the seat.

Move the seat forward and free the three tabs from the bar on the frame. Lift out the seat.

Installation

Fit the seat into place. Slide the three tabs on the back of the seat under the bar on the frame.

Guide the latch onto the pin. Push down on the front of the seat so that the latch closes securely.

Side Covers

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Net Doors

Disconnect the net door clips and free the Velcro strips.

Remove the two upper and two lower net door bolts with a 10 mm socket.

Hold the rear clip strap bolt with an Allen and loosen the nut. Remove the rear clip strap.

Remove the three front clip strap bolts with a 10 mm socket. Remove the front clips strap.

Lower Side Covers

Remove the three lower side cover bolts with a 10 mm socket. Note: two of the bolts should already be removed with the net doors.

Free the lower side cover tabs and remove the lower side covers.

Front Side Covers

Each side cover is held on by 5 bolts and a trim clips. The four lower bolts should be already be removed when taking off the net doors and lower side covers.

Remove the trim clip. Remove the upper bolt with a 10 mm socket.

Remove the front side covers.

Rear Side Covers

The rear side covers are held on by six trim clips and three bolts. The bolts should be already be removed when taking off the net doors and lower side covers.

Temporarily remove the gas cap when removing the right rear side cover.

Remove the two rear trim clips.

Remove the two lower trim clips.

Remove the two side trim clips.

Remove the rear side covers.

Install the gas cap.

Installation

Rear Side Covers

Temporarily remove the gas cap when installing the right rear side cover.

Fit the rear side cover into place.

Install the two side trim clips.

Install the two lower trim clips.

Install the gas cap on the right side.

Front Side Covers

Fit the front side cover into place.

Install the upper bolt and trim clip. Tighten the bolts securely with a 10 mm socket.

Lower Side covers

Fit the lower side cover into place.

Guide the tabs on each end of the lower side cover into the front and rear side covers.

Install the rear side cover bolt and tighten it to specification with a 10 mm socket. Install the other two bolts with the net doors.

Net Doors

Install the front clips strap. Insert the three front clip strap bolts and tighten them securely with a 10 mm socket.

Install the two lower net door bolts and tighten them securely with a 10 mm socket.

Install the rear clip strap. Hold the rear clip strap bolt with an Allen and tighten the nut securely.

Fasten the net door clips and Velcro strips.

Skid Plates

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Rear Skid plate

Remove the four bolts from the rear skid plate with a 10 mm socket. Free the tabs from the center skid plate by sliding the rear skid plate back. Remove the rear skid plate.

Center Skid Plate

Remove the 10 center skid plate bolts with a 10 mm socket. Slide the center skid plate back and free it from the front skid plate. Remove the center skid plate.

Front Skid Plate

Remove the eight front skid plate bolts with a 10 mm socket. Move the front skid plate forward and remove it.

Installation

Front Skid Plate

Fit the front skid plate into place. Install the eight bolts and tighten them securely with a 10 mm socket.

Center Skid Plate

Set the center skid plate into place. Install the eight outer bolts and tighten them securely. Wait to install the two rear bolts with the rear skid plate.

Rear Skid plate

Install the rear skid plate so that its tabs engage with the center skid plate. Install the four bolts and tighten them securely with a 10 mm socket.

Wheels

Wheels and Wheel Hubs

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

TROUBLESHOOTING

Front wheel wobbling

Rear wheel wobbling

Removal

Front Wheel Removal

Brake the wheel nuts loose a 17 mm socket.

Use a jack to raise the front wheels off the ground.

Remove the four wheel nuts. Remove the front wheel.

Front Wheel Hub Removal

Remove the cotter pin and discard it.

Apply the front brakes and remove the axle nut with a 30 mm socket.

Remove the caliper. See the Front Caliper topic for more information.

Note: Do not use the front brake while the caliper and brake pads are not installed on the vehicle.

Slide off the wheel hub assembly.

To remove the brake disc take out the four disc brake bolts with a 6 mm Allen wrench. Separate the disc brake from the wheel hub.

Installation

Front Wheel Hub Installation

Install the disc brake onto the wheel hub. Install four new bolts to specification with a 6 mm Allen wrench.

| ITEM | N-m | kgf-m |

| Brake disc bolt |

Apply grease to the wheel hub splines.

Slide on the wheel hub assembly.

Thread on the wheel hub nut.

Install the caliper. See the Front Caliper topic for more information.

Apply the front brakes and tighten the axle nut to specification with a 30 mm socket.

| ITEM | N-m | kgf-m |

| Front axle hub nut |

Install a new cotter pin and bend it to secure the nut.

Front Wheel Installation

Place the wheel on the hub.

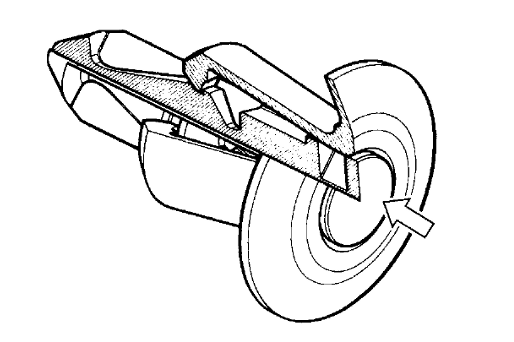

Make sure the tire rotation direction is correct. The arrow indicates the direction in which the tire should turn going forward.

Thread on the wheel nuts with their curved side facing toward the wheel.

The wheel nuts can only be installed as shown.

Tighten the wheel nuts with a 17 mm socket. Lower the front wheels to the ground and torque the nuts to specification.

| ITEM | N-m | kgf-m |

| Front wheel and front wheel hub |

Wheel Inspection

Check the wheels for damage.

Measure the wheel runout with a wheel stand and dial gauge. The lateral and vertical runout limits are both 2 mm (0.08 in).

Rear Wheels

Rear Wheel Removal

Brake the wheel nuts loose a 17 mm socket.

Use a jack to raise the rear wheels off the ground.

Remove the four wheel nuts. Remove the rear wheel.

Rear Wheel Hub Removal

Remove the cotter pin and discard it.

Hold the brake and loosen the wheel hub nut with a 30 mm socket.

Remove the wheel hub nut.

Slide off the rear wheel hub. Inspect the hub for damage.

Inspect the rear wheel hub dust seal in the axle housing. Replace it as needed.

Rear Wheel Hub Installation

Apply lightweight lithium-soap base grease onto the wheel hub splines, rear axle splines and dust seal of the axle housing.

Fit the rear wheel hub onto the axle.

Thread on the rear wheel nub nut.

Hold the rear brake and tighten the hub nut to specification with a 30 mm socket.

| ITEM | N-m | kgf-m |

| Rear wheel hub nut |

Install a new cotter pin and bend it to secure the nut.

Rear Wheel Installation

Place the wheel on the hub.

Make sure the tire rotation direction is correct. The arrow indicates the direction in which the tire should turn going forward.

Thread on the wheel nuts with their curved side facing toward the wheel.

The wheel nuts can only be installed as shown.

Tighten the wheel nuts with a 17 mm socket. Lower the rear wheels to the ground and torque the nuts to specification.

| ITEM | N-m | kgf-m |

| Rear wheel hub nut |

Wheel Bearings

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Front Bearings and Seals

Removal

Remove the front wheels. See the Wheels and Wheel Hubs topic for more information.

Remove the steering knuckle. See the Steering Knuckles topic for more information.

Disassembly

Remove the outer dust seal from the steering knuckle and discard it.

Remove the inner dust seal from the steering knuckle and discard it.

Check that the bearings rotate smoothly and do not bind. Replace as needed.

Remove the snap ring with a pair of snap ring pliers.

Driver Method

Drive the bearing out with a bearing driver tool from the inside out. Heat the area around the bearing to aid in removal.

Press Out Method

Press out the bearing with a press if available.

Remove the bearing and replace it with a new one.

Assembly

Place the new bearing in a freezer for at least a half hour before installation. Heat the knuckle.

Install the new bearing using one of the two methods below.

Drive In Method

Drive in a new bearing with a suitable driver with the same outside diameter as the bearing. The manufactures markings on the bearing must face out.

Press In Method

Press the new bearing in by its outside diameter.

Install the snap ring with a pair of snap ring pliers. Be sure it fits securely into its groove.

Apply lightweight lithium-soap base grease to the lips of the new dust seals Install the dust seasl with a suitable driver with the same outside diameter as the seal.

Special Tool-

Oil Seal and Bearing Driver: A120E00014

Installation

Install the steering knuckle. See the Steering Knuckles topic for more information.

Install the front wheels and hubs. See the Wheels and Wheel Hubs topic for more information.

Check the toe-in. See the Toe-In Adjustment topic for more information.

Rear Bearings

Remove the rear wheels and hubs. See the Wheels and Wheel Hubs topic for more information.

Remove the shock absorbers. See the Rear Shock Absorbers topic for more information.

Remove the rear knuckle. See the Rear Suspension Arms topic for more information.

Inspect the half shafts and wheel hub knuckle dust seals for damage and deterioration.

Remove the side dust seals and the pivot collars. Inspect the side dust seals and collars. Replace these components as needed.

Inspect the bushings and replace them as needed.

Knuckle Bearing Replacement

Inspect the knuckle bearing by turning it with a finger if the bearing doesn’t turn smoothly it must be replaced.

Remove the wheel hub side dust seal.

Remove the half shaft side dust seal.

Remove the bearing snap ring with snap ring pliers.

Drive out the bearing from the half shaft side of the knuckle. Heat the knuckle around the bearing to aid removal. Use a press if available.

Special Tool –

Oil Seal and Bearing Driver: A120E00014

Place the new knuckle bearing in a freezer for at least a half hour before installation.

Heat the knuckle around the bearing cavity to aid installation. Drive in the new knuckle bearing from the wheel hub side of the knuckle.

Install the bearing retainer snap ring into the groove with snap ring pliers.

Lubricate the dust seals with lightweight lithium-soap bases grease to the lips of the dust seals. Drive in the dust seals with a suitable driver with the same outside diameter as the dust seals.

Install the rear knuckle. See the Rear Suspension Arms topic for more information.

Install the shock absorbers. See the Rear Shock Absorbers topic for more information.

Install the rear wheels. See the Wheels and Wheel Hubs topic for more information.

Brake System

Front Caliper

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Warning: Brake fluid is very caustic and can damage paint, chrome and plastic. Wipe up any spills immediately.

Removal

Remove the front wheels. See the Wheels and Wheel Hubs topic for more information.

Drain the brake fluid. See the Brake Fluid topic for more information.

Note: If you are only replacing the brake pads it is not necessary to drain the brake fluid.

Loosen the two brake pad mounting pins with a 5 mm Allen wrench.

Remove the two brake pad mounting bolts with a 12 mm socket.

Note: Do not use the front brake while the caliper and brake pads are not installed on the vehicle.

Remove the brake caliper.

Brake Pad Replacement

Remove the brake pad pins.

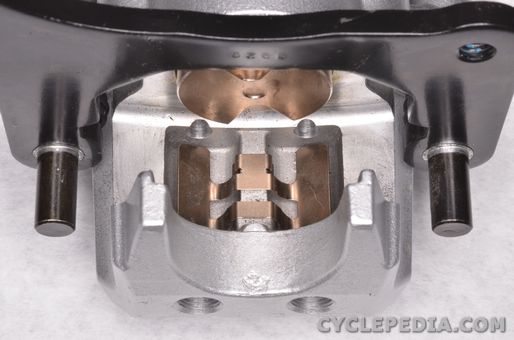

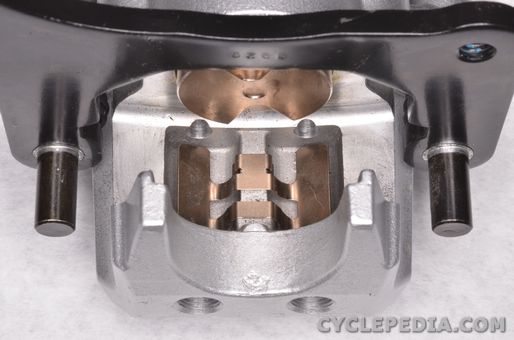

Compress the brake caliper holder.

Remove the brake pads and replace them if needed. Always replace them as a set.

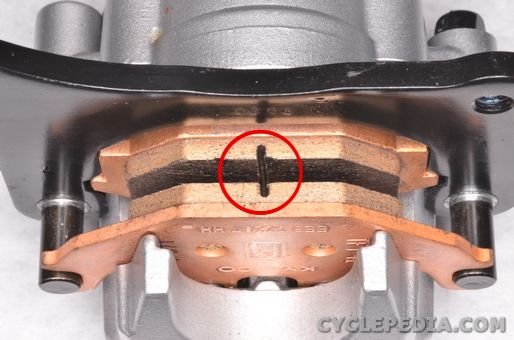

Replace the brake pads if the wear indicators are worn away.

Install the brake pads. See the Installation topic for more information.

Disassembly

Loosen the brake hose banjo bolt with a 12 mm socket. Remove the banjo bolt and sealing washers.

Remove the brake pad spring.

Remove the caliper bracket.

Remove the rubber boots. Replace if damaged.

NOTE: Always wear safety glasses when using compressed air and never point it directly at yourself or anyone else.

Place a thick rag over caliper piston and use compressed air to move the piston out. Do not place your fingers over the caliper piston while removing it as serious injury could result.

Remove the caliper piston by hand.

Remove the dust seal from the outer caliper bore and discard.

Use a mechanics pick to remove the piston seal from the inner caliper bore and discard.

Inspection

Check the brake caliper bore for any scratches, damage or excessive wear. Clean the brake caliper bore with DOT 4 brake fluid. Do not dry off with a rag.

Check the piston for any scratches, damage or excessive wear. Clean the piston with DOT 4 brake fluid. Do not dry off with a rag.

Check the brake caliper holder for damage.

Assembly

Note: Coat the new seals with DOT 4 brake fluid.

Install a new piston seal into the inner caliper bore groove.

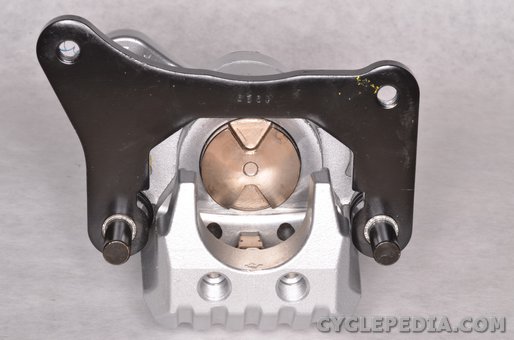

Coat the caliper bore and piston with DOT 4 brake fluid. Install a new dust seal onto the piston as shown.

Install the piston into the caliper bore.

Install the rubber boots.

Apply silicone grease to the caliper bracket pins. Install the caliper bracket.

Install the brake pad spring.

Installation

Install the brake pads.

Install the two the brake pad mounting pins into the caliper and through the brake pads.

Install the brake caliper.

Install the two brake pad mounting bolts and tighten them to specification with a 12 mm socket.

| ITEM | N-m | kgf-m |

| Brake caliper mounting bolt |

Tighten the pad pins to specification with a 5 mm Allen wrench.

| ITEM | N-m | kgf-m |

| Brake pad mounting pin |

Install new sealing washers and tighten the brake hose banjo bolt to specification with a 12 mm socket.

| ITEM | N-m | kgf-m |

| Brake hose banjo bolt |

Install the front wheels. See the Wheels and Wheel Hubs topic for more information.

Fill the master cylinder reservoir with brake fluid and bleed the brakes. See the Brake Fluid topic for more information.

Check that the brakes work properly before riding.

Front Disc Brake

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Inspection

Remove the front wheels. See the Wheels and Wheel Hubs topic for more information.

Check the front brake discs for damage or excessive wear.

Measure the brake disc thickness with a micrometer. Replace both rotors as a set if any are below the service limit.

| STANDARD mm (in) | 3.8 – 4.2 (0.152 – 0.168) |

Using a dial gauge and stand measure the disc brake runout. Replace both rotors as a set if any are below the service limit.

| ITEM | LIMIT |

| Brake disc runout | 0.30 mm (0.012 in) |

Removal

Remove the cotter pin and discard.

Apply the front brakes and remove the axle nut with a 30 mm socket.

Remove the caliper and support it. See the Front Caliper topic for more information.

Note: Do not use the front brake while the caliper and brake pads are not installed on the vehicle.

Slide off the wheel hub assembly.

Remove the four disc brake bolts with a 6 mm Allen wrench. Separate the disc brake from the wheel hub.

Installation

Install the disc brake onto the wheel hub. Install four new bolts to specification with a 6 mm Allen wrench.

| ITEM | N-m | kgf-m |

| Brake disc bolt |

Apply grease to the wheel hub splines.

Slide on the wheel hub assembly.

Thread on the wheel hub nut.

Install the caliper so the disc brake is between the brake pads. See the Front Caliper topic for more information.

Apply the front brakes and tighten the axle nut to specification with a 30 mm socket.

| Item | N-m | Kgf-m |

| Front axle hub nut |

Install a new cotter pin.

Install the front wheels. See the Wheels and Wheel Hubs topic for more information.

Check that the brakes work properly before riding.

Brake Pedal

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Remove the pedal cover. See the Pedal Cover topic for more information.

Remove the master cylinder rod clip and pivot pin. Separate the master cylinder rod from the brake pedal.

Remove the return spring and stop switch spring from the brake pedal.

Remove the E-ring from the brake pedal. Remove the brake pedal.

Installation

Lightly coat the brake pedal pivot in grease. Install the brake pedal. Install the E-ring and be sure it fits properly.

Install the return spring and stop switch spring onto the brake pedal.

Install the master cylinder rod pivot pin and clip onto the brake pedal.

Install the pedal cover. See the Pedal Cover topic for more information.

Master Cylinder

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Warning: Brake fluid is very caustic and can damage paint, chrome and plastic. Wipe up any spills immediately.

Removal

Lift the hood. See the Hood topic for more information.

Remove the front cargo box. See the Hood topic for more information.

Remove the pedal cover. See the Pedal Cover topic for more information.

Remove the brake fluid drain bolt to drain the brake fluid. Install the bolt after draining and tighten securely.

Note: Do not splash brake fluid onto any rubber, plastic and coated parts. When working with brake fluid, use shop towels to cover these parts.

Note the position of the position of the two brake lines on the master cylinder. Remove the two brake hose banjo bolts from the master cylinder with a 12 mm socket. Discard the sealing washers.

Note: When removing the brake fluid hose bolt, be sure to place towels under the hose and plug the hose end to avoid brake fluid leakage and contamination.

Remove the two master cylinder mounting bolts.

Remove the master cylinder rod clip and pivot pin. Remove the master cylinder.

Note: The master cylinder can not be repaired. Replace the assembly with a new one.

Installation

Install the master cylinder. Install the master cylinder rod pivot pin and clip onto the brake pedal.

Install the two master cylinder mounting bolts. Tighten the master cylinder bolts to specification.

| ITEM | N-m | kgf-m |

| Master cylinder mounting bolt |

Note: Do not splash brake fluid onto any rubber, plastic and coated parts. When working with brake fluid, use shop towels to cover these parts.

Connect the brake hoses to the master cylinder. Use new sealing washers with the banjo bolts. Torque the banjo bolts to specification with a 12 mm socket.

| ITEM | N-m | kgf-m |

| Brake hose banjo bolt |

Fill the master cylinder with fresh brake fluid from a tightly sealed container and bleed the brakes. See the Brake Fluid topic for more information.

Check that the brakes work properly before riding.

Install the front cargo box and close the hood. See the Hood topic for more information.

Install the pedal cover. See the Pedal Cover topic for more information.

Front Brake Lines

SAFETY FIRST: Protective gloves and eyewear are recommended at this point.

Removal

Remove the front wheels. See the Wheels and Wheel Hubs topic for more information.